Why IES

When Our Client’s Succeed, We Succeed!

With an exceptionally short ROI, profitability is right around the corner.

Industry Leading Botanical Extraction Equipment Suppliers

Relationship Oriented

As an essential oil extraction machine supplier, IES is directly linked to the success of each client by dedicating a team of professionals to every opportunity.

Through communication, collaboration, and continued education, we build the foundation for mutual success. Building long- lasting relationships allow us to provide the botanical extraction solution for every phase of our clients’ business, no matter how large or small the extraction needs may be.

Preventative Maintenance

In order to ensure uptime, IES offers several levels of service packages customized around your production schedule. Regular service quality assessments ensure continued improvement and satisfaction. We strive to exceed customer expectations with prompt response time for any extractor repair or maintenance.

Education

We believe in constant reinvention through education and experience. Being open to improvement and change expands the bounds of possibility for your business.

IES offers several levels of classes for education in carbon dioxide, CO2 as a solvent, solvent manipulation for extraction, equipment handling, safety protocols, and production schedules. Our certification program enables our clients’ production teams to harness the potential of supercritical CO2 extraction while using an IES system.

Quality & Consistency

Customer Success

Capital equipment purchase, specification information, functionality, build time, facility layout, shipping, crating, timing, educating, and training are a few of the hurdles we help our clients navigate as a top botanical extraction equipment supplier.

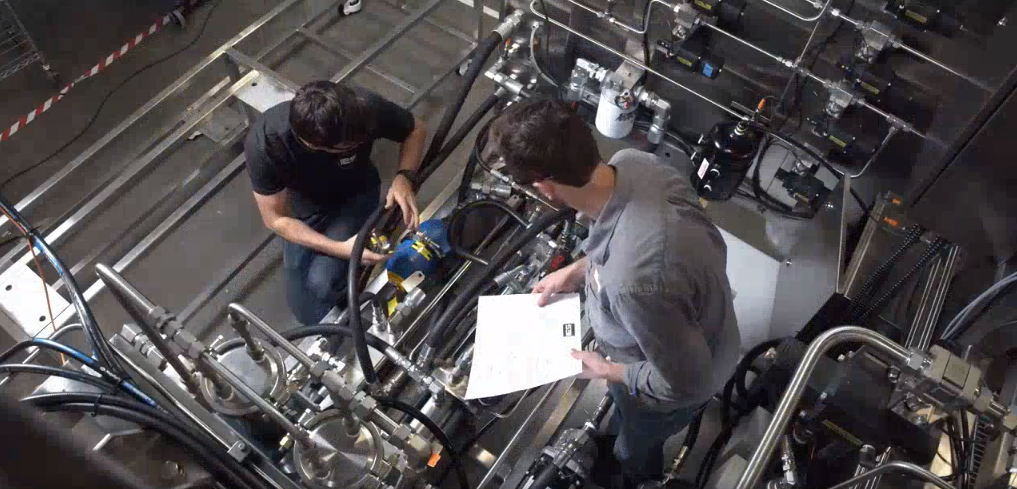

To ensure success, IES dedicates a single point of contact to every customer for quality and consistency of communication to ensure the success of each client. Included with every essential oil extraction machine purchase is an onsite training and commissioning from one of our service professionals. IES proves functionality, at your facility, with live support for your supercritical CO2 extraction equipment, and provides ongoing support to fit operations of any scale.

Why CO2 with IES Botanical Extraction Equipment?

- Accurate and stable process parameters allow easy manipulation of solvent conditions, enabling a reduced product loss and costs associated with post processing techniques.

- Ability to isolate terpenes, while controlling desired levels of oils and wax in the extract.

- Quick run times for efficient production.

- No degradation of plant matter.

- Non-flammable, non-toxic solvent extraction.

- Proprietary software with data storage.

- Quality training and educational resources provided by our customer relations team.

- Dedicated service team throughout the ownership of an IES CO2 Extraction Machine.

- On-site commissioning and facility preparations provided to each client.

- Continued development into improving technologies and service to benefit our clients.

Co2 As A Solvent

Components Of Co2 Extracts

Process Optimization

- Data Analysis

- Best Practices

- Process Review

- Site Inspections

- Case Studies

- Practical Recommendations

Preventive Maintenance

Pure Extraction

IES offers

Our Extractors Offer

- Industry Leading Flow-Rates

- Engineered Heat Exchangers For Optimal Temperature Control

- Hydraulically Driven Gas Booster Pump

- Wide Range of Parameters

- Industry Leading Proprietary Software

- 100% True Automation

- 100% Shelf Ready Oil Products

- Fully Automated Control System

- Easy Open Enclosures for Quick Access to Materials

- Sub & Supercritical Extraction Capabilities

- Industry Leading Run-Times

- 100% Communication with Ancillary Equipment

- Mobile Casters

The Co2 Advantage

Why Use Supercritical CO2 Extraction Equipment?

Our extraction machines utilize CO2 to separate oil extracts from their original form. CO2 is a readily available and cost-effective gas that is non-toxic and can be used safely to extract oils from spices, herbs, coffee, and other natural plants. CO2 is pumped into the botanical extractor machines at high pressure in order to accomplish the extraction process and then evaporates, leaving pure botanical oils without the chemical residue that is usually associated with butane extraction. Our botanical extractor machines can run at moderate temperatures that are less than 100 degrees Celsius without damaging the original product. This quick and efficient process helps businesses achieve faster returns on their investment due to the low production cost of high-quality end products.

Equip Your Business With Isolate Extraction Systems

Our specialty is manufacturing high-quality, food-grade botanical extractor machines that can easily handle the demands of your operation. Since 2012 we have been developing modern technology for supercritical CO2 extraction equipment that focuses on safety, efficiency, reliability, and practicality. We use C02 because it doesn’t leave a residue and won’t alter the oil’s natural chemical composition. This means that the oil you produce is as pure as possible which can drastically enhance the quality of your end products.

At Isolate Extraction Systems we are committed to supporting your business with solutions that have been specially designed to meet your needs, and the quality of our botanical extractor machines is proof of that commitment. Contact us today to receive a quote for your business and take your oil production operation to the next level with supercritical CO2 extraction equipment.

What Makes Isolate Extraction Systems’ Botanical Extractor Machines Special?

We manufacture our botanical extraction equipment in several sizes to accommodate operations of various scales. Each machine offers the same ability to efficiently extract oils for a variety of purposes including essential oils, everyday consumable products, and pharmaceutical applications.